This complete Manual Handling Powerpoint presentation can be purchased here

manual handling working conditions

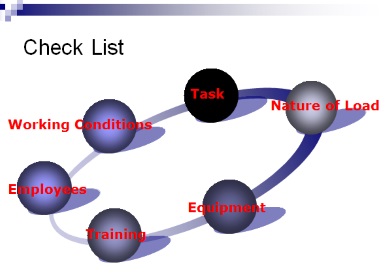

In order to establish if a company is complying with the manual handling regulations, one of the things that should be checked are the conditions that the employees have to work in and their relevance to manual handling.

The list below will not apply to every company but the relevant ones should be selected.

- The general layout of the plant. Is it conducive to good manual handling?

- The lighting. Is it adequate for the task?

- The ceiling height. Does the height prevent good manual handling practices? For example bending down under a racking

- The precise location. It takes more out of the body to accurately locate a heavy object

- The distance moved. Carrying a load a long way is obviously more difficult

- The gangway widths. Do they allow enough space for correct manual handling?

- The floor conditions. Many handling operations are the results of trips

- Any obstructions? This includes moveable ones such as pallet trucks etc.

- The ambient temperature. Extreme temperatures tend to prevent us from thinking about anything else!

- Any steps or ladders in use. There may be no hand hold when carrying an object

- The wind. If working outside with bulky loads wind may be a factor

- Visibility. Maybe the size of the load being carried prevents the employee form seeing ahead

Obviously all of the above need to be taken into account when doing the risk assessments.