Forklift feature articles

The largest forklift operator training website in the world

![]()

![]()

Load centre on counterbalanced forklift trucks

One of the most common searches on this website is the phrase "load centre". I can understand why as it seemed to be a major problem for trainees when I was teaching forklift operators. In particular, the question on the theory paper used to cause much confusion.

This page is devoted to explaining a forklift truck's load centre, the definition of both horizontal and vertical load centres and the importance of understanding them if you are a forklift operator.

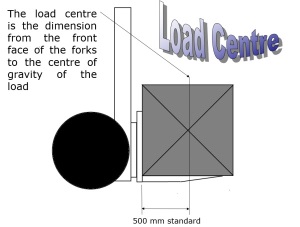

Check out this picture. As it says on the caption "the load centre is the dimension from the front face of the forks to the centre of gravity of the load".

When a forklift truck is being designed it is essential for the designers to know this dimension else they couldn't do the maths needed to design the truck!

With that in mind they use the reverse argument. "We will tell you how long your load must be in order to use this forklift safely". Standardised modern loads tend to be 1m in length and so, nowadays, that is the dimension used for a "standard" load. It follows, therefore that, assuming the load is carried hard up against the front of the forks of the forklift, that the distance to the middle of the load will be half a metre or 50 cm.

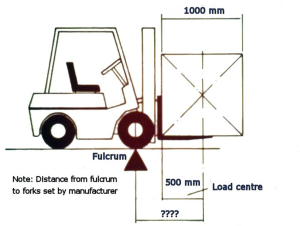

To complete the story look at this picture. In order to design the forklift truck the engineers need to know the dimension I have shown with lots of question marks. It is the distance from the centre of the front wheels of the truck to the centre of gravity of the load.

This is the dimension needed in order to design the forklift. Don't worry about the maths involved as we don't need to know it for this explanation. The folks designing the forklift truck do actually know the dimension at "A" which, by the way, is known as the Lost Load Centre. They can work this out because it's within their control as it depends on such things as the diameter of the wheels and design of the mast etc.

Taking this dimension "A" they simply add 500 mm to it, (which they know is a standard) and they now have the dimension which is shown with question marks. Once they have this, they do a series of calculations known as "moment calculations" These enable them to calculate how much weight/distance is needed on the rear end of the forklift.

Obviously not all loads are a standard 500 mm. The old U.K. standard was 600 mm or 24 ins and some of these machines are still around. Some specialist trucks such as narrow aisle, man up machines use 400 mm.

From an operator's point of view what matters is what's shown on the forklift's capacity plate. Full details on reading capacity plates can be found here. ANY increase in the load centre, (caused by a load too long or not having the forks properly inserted), can cause the forklift truck to tip over in a forward direction.

In addition to a horizontal load centre described on this page, a forklift truck also has a vertical load centre. Details of this can be found on this page.