Complete Powerpoint slide presentation for forklift instructors. Ready made training course

How are your forklift tyres?

Here is a useful article by Forklift, Saskatchewan about tyres and tyre wear/damage on forklift trucks. I have Anglised the article only.

Here is a useful article by Forklift, Saskatchewan about tyres and tyre wear/damage on forklift trucks. I have Anglised the article only.

One fact that is not well known is that forklift trucks don’t have any suspension. As a result, everything rides on the tyres. Tyres are essential for softening the ride your employee, equipment and product experiences. So when your tyres are low so is your forklift.

You should realize that the average forklift tyre is carrying over 9600 pounds on the drive tyres, and about 1300 pounds on the steer tyres when laden and they do this while your truck turns, stops and accelerates getting the load to and from points within your workplace. To do this safely tyres should be in the best condition possible while it lives through its wear life, [anywhere from a thousand running hours or more dependent upon your floor conditions and use]. So lets look at your tyres and discuss the type of wear you may see and why.

First of all there are cushion tyres. Since they are made of vulcanised rubber, they wear slowly but can be damaged easily. Some of the types of wear you may see are;

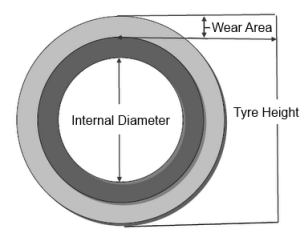

1. Simple wear: Your forklift tyres have a 50% wear line; it’s just above the tyre size. When the top of the tyre meets the wear line it’s time to start thinking of replacing the tyres.

2. Chunking: Pieces of the tyre rubber are falling off, caused by litter or debris on the floor, spinning over rough surfaces, or striking objects while in use. This is a harsh one, often a great cause of the truck rattling while being driven.

3. Tearing at the surface: Caused by littered floors embedding foreign materials, bad dock plates or running across sharp machinery edges

4. Flat spots:. When the truck, personnel and product are shaken as they move. This is often caused by spinning the tyres during acceleration, frequent sharp turns under heavy load, or misadjusted brakes.

When it comes to Pneumatic tyres, the issues are different. Here you need to pay attention to;

- Under inflation: This can compromise stability and accelerates wear. Use the pressure settings on the side of the tyre as a guide to what pressure to maintain. Moreover making hard turns under load with an under inflated tyre can fold the tyre, causing it to let loose of the rim resulting in a violent shift in the equipment and load. Under inflation will also reduce your lift trucks fuel efficiency.

- Over inflation: This will result in less stopping power due to a lessening of the tyre's traction. It will also cost you more through expedited wear.

- Sidewall cuts from objects struck by the tyre threaten sudden shifts in the unit with the loss of air pressure, and in the case of foam filled tyres will allow the fill to ooze out causing the unit to lean in the direction of the damaged tyre.

- Over worn solid or resilient tyres can cause the lift truck to run rough or shake on harder surfaces, reducing the driver’s ability to control the unit, and reducing the stability of the load.

Tyres that are worn or low can cause several problems for the forklift owner and operator. Tyre wear never happens evenly on a forklift and therefore your forklift can become unstable . Low tyres mean that your forklift has a greater chance of a transmission housing becoming damage by hitting a dock plate or debris on the floor.

Also remember the smaller the tyres, the faster they turn and the harder your transmission works, which could lead to overheating . Damaged tyres will lead to greater vibration of the forklift, which often leads to accelerated equipment and driver fatigue. An overly tired operator is often unsafe and a fatigued forklift will begin to have repair issues. So pay attention to the condition of your forklift tyres.

http://forkliftsaskatchewan.blogspot.com/

Disclaimer. The legislative information contained on this web site is my interpretation of the law based on many years in the health and safety business. A definitive interpretation can only be given by the courts. I will therefore not be held responsible for any accident/incident/prosecution arising as a consequence of anyone using any information obtained from this web site.